Friday Feb 27, 2026

Friday Feb 27, 2026

Thursday, 22 July 2021 00:00 - - {{hitsCtrl.values.hits}}

The Sri Lankan garment sector comprises around 400 factories. About 4 in 10 are large facilities; one third are medium sized and the rest are small enterprises. A big lesson small and medium enterprises (SMEs) can learn from larger firms is that it pays to listen to the demands of environmentally conscious global consumers and fashion brands. At manufacturing level, that translates to continuous innovation and a strong commitment to sustainability in all operations. .

that it pays to listen to the demands of environmentally conscious global consumers and fashion brands. At manufacturing level, that translates to continuous innovation and a strong commitment to sustainability in all operations. .

“The factory was clean enough to eat off the floor”, observed Pulitzer winner, Thomas L Friedman in The Lexus and the Olive Tree, his 1999 book on understanding globalization. "In terms of working conditions, this factory was world-class... I would let my own daughters work there."

He was talking about a visit to Slimline, a MAS Holdings facility. This and many other observations were an accolade for MAS Holdings. It was also a nod to Sri Lanka's potential as a world class manufacturing destination serving the global economy.

Today, the Sri Lankan garment sector knows beyond doubt that sustainable practices—in manufacturing and labour fronts—enable us to negotiate a higher proportion of a garment’s retail value. Investments into R&D, design, procurement and marketing enable large companies command higher prices. There are also many production level activities that can help SME apparel makers leapfrog towards more greener reputations.

Greener Manufacturing Processes

Sustainable apparel is made with environmentally friendly factories. SMEs can score high on key sustainability metrics by investing in sustainable manufacturing practices such as Cleaner Production and Zero Waste.

The highest volumes of chemicals and water are used during the wet processes of textile dyeing and finishing, yarn dyeing, milling of fabrics, laundry, washing and finishing and printing facilities.

Wastewater treatment plants (WWTPs) remove toxic chemicals before discharging water to the environment. The Board of Investment of Sri Lanka operates industrial park WWTPs that subject factory-treated wastewater to additional treatment before discharge. Factories outside parks invest in their own WWTPs, a significant financial burden for SMEs.

Even with WWTPs, failures and inefficiencies result in harmful chemicals entering the environment, including surface water bodies and streams. Extreme pollution leads to putrid, black streams that cannot support aquatic life. There are capacity and uneven loading issues that require more technological inputs and financial solutions.

What is Zero Discharge of Hazardous Chemicals (ZDHC)?

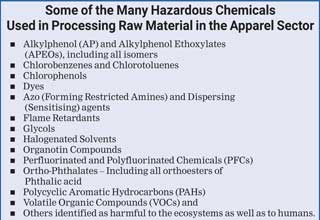

The ZDHC programme and the Roadmap to Zero aims to protect the planet and the people by reducing the chemical footprint of the textile, leather and footwear industries. With ZDHC the quality of wastewater discharge goes beyond regulatory requirements to include hazardous chemicals used in processing raw materials.

Many global fashion brands, chemical suppliers and manufacturers use the programme to achieve safer chemical inputs by avoiding harmful banned substances. The testing and monitoring are performed by ZDHC Accepted Laboratories and Certifiers.

Zero Discharge can be implemented at facility level or extend back to cover the entire supply chain. Sri Lanka is primarily a finished goods manufacturing nation. Local manufacturers with wet processes can begin their journey towards zero in small steps, beginning with their wastewater and sludge.

The first step is preventing wastewater contamination. In the long term, manufacturers can try to find ways to avoid using restricted chemical substances. Where this is unavoidable, removing harmful chemicals physically, chemically, or biologically before discharge of wastewater is a viable solution.

HSBC and IUCN have been

working together to formulate a strategy to build a more resilient apparel industry through adoption of greener practices. “A Road Map Towards a Greener Apparel Sector” report is the result of an extensive research conducted by the project team in partnership with the Joint Apparels Association Forum, Board of Investment Sri Lanka, National Cleaner Production Centre and Sri Lanka Bankers’ Association.

To access the full report visit

www.hsbc.lk/ApparelSectorResearch