Monday Feb 23, 2026

Monday Feb 23, 2026

Tuesday, 26 August 2025 02:25 - - {{hitsCtrl.values.hits}}

Background

Milk price is exorbitantly higher in Sri Lanka when comparing to the countries of the world. Sri Lanka shows the highest price gap for milk with the farm gate price and the retail price, as of now the farm gate price of a litre of milk is Rs. 200 while the retail price is up to Rs. 550 in a Tetra pack and a plastic one litre bottle is Rs. 480 further, 900 millilitre in polythene pack is Rs. 380. This is what the problem that the analyses should be. This is a problem of the logistics/supply chain. The basic theory of the supply chain is; the supplier, the manufacturer and the market must have been in the range of reasonable distance. If I elaborate the theory more with an example; “Supplier is in Jaffna, factory is at Digana (Kandy) and again the market is in Jaffna”. This is one of the real situation theory that can observe in the country in order to elaborate the wrong and long logistic model.

Milk price is exorbitantly higher in Sri Lanka when comparing to the countries of the world. Sri Lanka shows the highest price gap for milk with the farm gate price and the retail price, as of now the farm gate price of a litre of milk is Rs. 200 while the retail price is up to Rs. 550 in a Tetra pack and a plastic one litre bottle is Rs. 480 further, 900 millilitre in polythene pack is Rs. 380. This is what the problem that the analyses should be. This is a problem of the logistics/supply chain. The basic theory of the supply chain is; the supplier, the manufacturer and the market must have been in the range of reasonable distance. If I elaborate the theory more with an example; “Supplier is in Jaffna, factory is at Digana (Kandy) and again the market is in Jaffna”. This is one of the real situation theory that can observe in the country in order to elaborate the wrong and long logistic model.

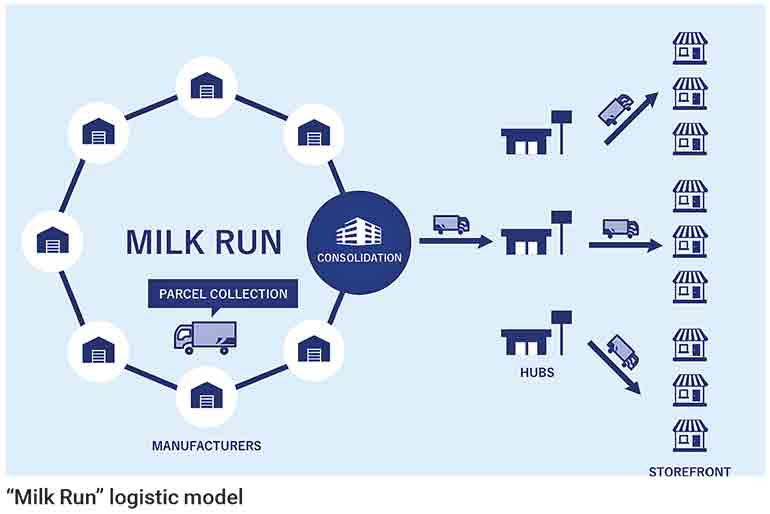

In order to elaborate more of this concept, I will elaborate a milk processing and distribution model which prevailed in the country during the decades of 60’s and the 70’s done by Government owned “Milk Board”. There were small scale milk processing factories were in almost all the big townships, board targeted the milk farmers around the range of 10 km, and 2000 Liter bowser went to the field to collect the milk from milk farmers, but some farmers brought to the processing factory. After pasteurising the milk (pasteurising or UHT is the best method to preserve the milk without adding chemicals), Milk Board distributed to the “Milk Bars” and shops around their given territory generally around 10 km. and total supply chain completed within 24 hrs. supplying the milk to the customer, restricting the word to the “Fresh”. This product came in returnable glass bottles filled by fresh milk with a basic aluminum lid by 6 a.m. to the market and customer used it for the morning tea. Population had the necessary purchasing power to purchase the fresh milk daily.

Milk has become a luxury FMCG (Fast Moving Consumer Good), many social levels with lower economic backgrounds cannot afford to this basic need, and according to social belief “Milk is a right of an Infant”. Country produce only 40% of the total milk consumption and balance 60% is imported from different countries, mainly as a milk powder. There are many children in this country who had not seen or ate cheese or butter, it consumes only above the upper middle class level. Then, what the observation is huge milk gap which no government considered for years because the 40% milk production was static for last 40 years. All governments were very happy with importing milk and deal with big multinational or Local companies for obvious reasons.

Present model of distribution and processing

Present business model is big factory model that process 3 lakh litres per day or less, and the companies collect milk from all over the country and distribute again all over the country, covering long distance, creating huge transportation and logistics cost for storage and other matters, subsequently reducing the quality of the milk. The local/Sri Lankan-based companies mostly use tetra pack, which gives a long shelf life like five and a half months, two and a half months for polythene pack, and four days for the plastic bottle only, which is accepted. A liquid milk imported from Pakistan has 12 months shelf life. Tetra pack is very costly, and apart from transportation, consumer spends around 20% for the pack. The question is, as a small island, does the country need five and a half months or two and a half months of shelf life?

This is how the processing capacity of some of the factories in the country: Pelawatta – 3 lakh litres/day, Ambewela – 3 lakh litres/day, Digana – 50,000 litres/day, Colombo – 50,000 litres/day in 14 acres of land at Narahenpita. Certain companies describe about the ERP systems which the company says logistics is scientific, but not considered the long logistic chain and the unacceptable shelf life.

Foreseeable solutions

The then Milk Board was a thriving organisation that worked on a practical supply, processing, and distribution model. But during the decade of the ‘60s, multinational companies encroached the country with the model of “milk powder”. The Government accepted the offer and established the first milk powder processing factory at Welisara with the brand name “Lakspray”. During the same period, multinational companies lobbied politicians, doctors, and media companies, and badly socialised the myth that fresh milk causes lung and “phlegm” problems in the human body.

With a good distribution network through “Sathosa” (Cooperative Wholesale Establishment), they approached the customer segment of the entire island and converted the masses to milk powder. Subsequently, the Government allowed the natural death of the then Milk Board and its foolproof supply chain and processing system.

To elaborate the supply chain of the then Milk Board: it was a world-renowned logistics model named “Milk Run”, which almost all countries still resort to and also apply to other logistics businesses.

The strategic suggestion is reverting back to the former Milk Board business model with necessary alterations. At the very least, each AGA division must have a processing factory, attracting suppliers in the surrounding areas and covering nearby markets. The model should be a PPP (Public–Private Partnership) and can provide an opportunity for supermarket chains like Cargills or Keells to operationalise the system, since they already have island-wide supply and collection networks that can be used in a trial model.

Further, negotiations can be held with already established companies with larger processing plants to adopt the small-plant model, while keeping the bigger plants for exports, other value-added dairy products, and for products intended for export markets that require longer shelf life.

Longer shelf life means deteriorating product quality due to the addition of many chemicals for extended preservation, along with a higher economic burden for a poor country like Sri Lanka. Developed countries are much more concerned about packaging, health, and economic viability—concerns which Sri Lankan authorities have not adequately addressed.

Furthermore, some companies in the country are abusing the word “Fresh” for liquid milk by adding powdered milk and using misleading terms like “milk solids”, which even deceive responsible authorities. Some companies use both terms—“milk solids” and “powdered milk”—contradictorily on the same pack to mislead consumers.

The long shelf life packs are imported from multinational giants, creating a huge burden on foreign currency, which is not sustainable for the country’s economic system. A more viable business model is the returnable glass bottle with an aluminium lid or plastic bottles with a four-day shelf life.

Fodder is another facet which cannot be avoided in terms of the quality and the quantity of milk production at the farmers’ level. Many farmers have given up cattle farming due to the difficult supply of fodder, which is a responsibility of the logistician in order to reason the unit price of the milk. The Government too does not have any plans for producing high-quality fodder for the farmer, but the raw materials to make good quality fodder are amply available in the country and are presently considered a menace to crop-growing farmers.

Guinea grass is one example which disturbs farmers by spreading in farmland as a weed, but it produces protein (4–14%) and yields up to 175 tons/hectare per year. In other words, to eradicate the Guinea grass from lands, farmers spend around Rs. 30,000 per acre by doing it manually or with a dozer, but what practically happens is spraying chemicals like glyphosate, which is more dangerous to the environment, though it costs only about Rs. 3,000 per acre compared to manual or mechanical methods.

There are many mechanical devices available in the market to collect this valuable fodder, which the country currently considers a troublesome weed. Also, there are many other weeds and trees like Ipil Ipil and Gliricidia which can be converted into valuable fodder and used to improve the cattle farming industry, which can help produce a litre of milk at a reduced cost.

Furthermore, a person who possesses a small land plot can rear a cow for their daily milk consumption without a huge burden. This model is a common hobby in many countries for farm-loving enthusiasts.

Milk bar concept

Milk bar is a good concept to popularise milk consumption among people. Thus, the Government is planning to introduce 200 milk bars to the market island-wide. A milk bar has to be an attractive place for customers. It is an outlet restricted only to milk and other dairy products, but in Sri Lanka, we find that the attractiveness of milk bars is extremely negative due to untidiness and poor customer care.

In other countries, a milk bar is an appealing space with soft-spoken, elderly, well-dressed males and females as salespersons. In the milk bar, no other product is sold apart from milk and dairy products. The beautiful space is filled with the attractive fragrance of milk, which draws people of all ages. Mobile units can also be introduced—similar to present-day ice cream vans and bicycles—with visual appeal, cleanliness, proper branding, and uniformed staff. Therefore, the Government needs to regulate these establishments with strict guidelines and consistent branding. Additionally, to make the concept more successful, a reduction in milk prices is a compulsory requirement.

Conclusion

The above paragraphs describe the social perception of milk, its processing systems, the present supply chain, its viability, and ways to reduce milk prices to affordable levels by using a scientific logistics model and supporting areas such as fodder management and customer-end applications. Furthermore, the article discusses the model previously used in the country as well as successful models from other countries. It also highlights some foreseeable restrictions in Sri Lanka, including cultural and religious limitations on business practices—such as slaughtering and the belief that milking twice a day violates the food requirements of the calf—which affect the reduction of the unit price.

Controlling and reducing the long supply chain and the extended shelf life are the most viable and considerable options to reduce the price of milk and create access for all segments of society, since milk is a basic human need. The present higher profit margins, as elaborated in the first paragraph, appear extremely unethical for the milk processing companies and the Government, and the nation cannot escape the blame.

I have meticulously elaborated on the “logistical” reduction models of the business in the previous paragraphs. As a related option, I have provided insights into fodder production and availability in the country to help develop the industry to the next level.

Since the Government has many organisations dedicated to developing the cattle industry, yet they have not improved production beyond 40%, the Government must set deadlines and targets for the relevant line organisations to increase local milk production by at least 10% per year until self-sufficiency is achieved—a long-awaited national requirement.

It is also worth mentioning that milk is one of the most lucrative businesses in the world. Furthermore, India became the biggest milk producer globally through a five-year targeted plan, which Sri Lanka too can consider.

(Author is a Chartered Logistician and can be contacted by [email protected])