Thursday Feb 26, 2026

Thursday Feb 26, 2026

Tuesday, 1 February 2022 00:17 - - {{hitsCtrl.values.hits}}

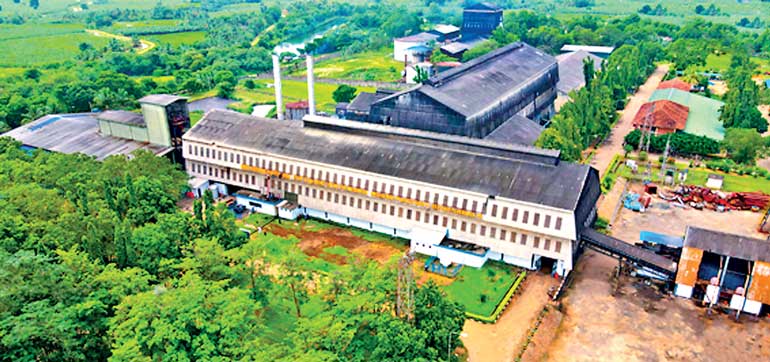

Pelwatta Sugar

By Chandani Kirinde

Lanka Sugar Company Ltd. (LSCPL), under which the Pelwatta and Sevanagala factories operate, has been hitting new targets in production in both sugar and ethanol since 2020, making profits and addressing longstanding issues faced by the around 6,000 workers attached to these two entities.

Janaka Nimalachandra who took over as Chairman of this fully Government owned company in 2020 which comes under the Ministry of Plantation Industries and Export Agriculture, has embarked on getting Pelwatta and Sevenagala factories to operate to their full capacity while motivating and encouraging the workers by making them part and parcel of the new phase of development of the two factories located in Monaragala where they are the biggest employer of residents of the district.

The Government took over both Pelwatta and Sevanagala factories in 2011 under the Revival of Under-performing Enterprises or Underutilized Assets Act passed by Parliament after nearly a decade under private ownership. In August 2012 Lanka Sugar Company Ltd., was incorporated bringing the two factories under one company.

Nimalachandra, who moved from the private sector to work in the state sector as the company’s Chairman, in an interview with the Daily FT said that while he faced many challenges early on which included increasing the area under the cultivation of sugarcane as well as motivating workers while dealing with the onset of the COVID pandemic, the results by the end of 2021 has been extremely good and encouraging.

“When I took over in 2020, I was given a company with Rs. 1.3 billion loss and no money to pay salaries to the farmers for their sugarcane and with zero stocks of sugar. My first hurdle was to find money to pay the salaries of the around 6,000 workers (4,500 at Pelwatta and 1,200 at Sevenagala). There are also around 10,000 farmers who directly supply the two factories but at any given time there are around 15,000 farmers, of whom 5,000 are outgrowers. Altogether in the Monaragala District, around 25,000 families depend on these two entities for their livelihood with the cultivated land spanning 35,000 acres.”

To address the immediate issue of worker salaries, Namalchandra decided to opt for a bank loan. The salary bill for Pelwatta was around Rs. 500 million while it was as close to Rs. 200 million at Sevenagala.

When he took over as Chairman, both factories combined had an overdraft of about Rs. 800 million but by the middle of last year, every single loan had been paid back and the Overdraft had come almost to zero. “We have the OD facility but we are not utilising it,” he added.

He also had to address many other issues faced by the workers and farmers other than settling salaries. “They had a mountain of issues. Some of the things are just shocking. There were employees who had worked for 30 years without getting permanent employment but were casual and contract workers. In the past two years 2,500 employees out of 6,000 have got a permanent job.

“Within one-week last year, 1,100 new accounts were opened at the Bank of Ceylon in Pelwatta. With secure employment they were able to take bank loans. Some bought bikes, others three-wheelers and there has been a transformation,” Nimalachandra added.

The problems of the farmers who provide the crop too had to be addressed. “The price paid by farmers for a metric ton of sugar cane had not been increased for years. At the time we took over they were paid Rs. 5,000. Immediately we increased it by 10% and in the past one and a half years we have increased it by Rs. 1,250 making it Rs. 6,250. We also increased the transport fee by 10%. We have reduced the interest on farmer loans from 12% to 8% last year and also frozen Rs. 480 million farmer loans.”

Around 1,000 staff residences which had been neglected for years too had to be repaired while the two factories too are being given an overhaul to make them welcoming for schoolchildren and other visitors who visit.

Sevanagala

Sugar stocks

Ban of ethanol imports

The decision by President Gotabaya Rajapaksa to ban the import of ethanol was a boon to the company. Ethanol is produced from molasses, a byproduct of sugar manufacture.

“When I took over there were stocks of ethanol but the buyers were not ready to pay even Rs. 290 for a litre but were importing and paying at the rate of Rs. 1,200 per litre. After the ban on the import of ethanol, the Government put the price per litre at Rs. 500 and found buyers.”

Nimalachandra said that the ban wasn’t an easy decision but it has paid dividends and for the past two years not a single barrel of ethanol has been imported into the country.

Farmers transporting sugarcane to the factories

Harvesting sugar cane

“Imagine if we had to bring down ethanol today, the outflow of foreign exchange would have been massive. We had to up our game. We had to look at our quality. The decision was made but I was put in the hot seat. There were complaints that the local ethanol is not good, that we cannot meet the demand but for the past two years we have managed that locally. The ethanol ban gave us a solid base to build on,” he emphasised.

The national requirement for ethanol in the country is between 23-25 million litres and last year Pelwatta and Sevenagala produced 13 million litres of ethanol. (Pelwatta around eight million litres and Sevenagala around five million). Gal Oya (Hingurana Sugar) and a private factory managed to provide the remaining amount to meet the local demand.

Keeping the farmers content is a key component to the success of the sugarcane industry. “Many people were moving away from sugarcane farming because it was not profitable. But in the past two years, even with the coronavirus outbreak and the ban on agrochemicals, we secured an adequate crop with 10,000 regular farmers providing stocks and another 5,000 outgrowers also joining them. We have built 40 mini reservoirs and provided irrigation facilities for thousands of hectares of land. We have provided a land preparation subsidy and a seed cane subsidy so as to attract them back to sugarcane farming.”

After Nimalachandra took over, with the assistance of the subject ministries, a five-year plan was drawn up and two years on, Lanka Sugar Company Ltd. is running at a profit. “In 2020, we had Rs. 1.1 billion in profits and in 2021 it was Rs. 1.6 billion. This is from a position of Rs. 1.3 billion loss in 2019.This is the highest profits ever made, higher dividends ever paid. Last year we gave bonuses twice for both farmers and staff of both factories,” he said.

Better varieties

There has been a lot of learning for Nimalachandra to do on the job particularly the nitty-gritty of sugarcane harvesting and one discovery he made was that Sri Lankan farmers are growing some of the worst varieties of sugarcane which give a poor yield as well as a low sugar recovery rate.

“For the past 18 years we have been focusing on one particular variety and we have foregone the good varieties. Last year with all we have achieved we still had the worst sugar recovery rate. It is not something that can be fixed overnight,” he said.

However, he has taken the first step to introducing farmers to better varieties of the crop with the assistance of the Sugar Research Institute (SRI).

“My team and I visited the Institute and asked for new varieties and found they had developed around 140 varieties of sugarcane. We took 40 new varieties for testing. It takes about three years for it to come to commercial planting. We have identified about 10 varieties to be planted at both Pelwatta and Sevenagala which will give double the sugar recovery we get today.”

The annual sugar requirement in the country is around 600,000 MT of which close to 90% is imported, spending about Rs. 45 billion annually. Till 2020, Sri Lanka only produced eight to nine percent of its national requirement.

“There are only three sugar producing factories in Sri Lanka, these two and Gal Oya (Hingurana) sugar factory. Last year, a small private entity came into operation so we have four. Last year we managed to meet 10 to 12% of the local demand for sugar.”

While the factories are situated in idyllic locations, elephants attracted by the sugarcane crop is a longstanding problem and one which Nimalachandra and his team have had to deal with.

“We look after around 250 kilometres of the elephant fence with 550 people and about 40 tractors patrolling the length and breadth of the fence 24/7. We work with the wildlife authorities but the patrolling is done 100% by us,” he said.

In dealing with the coronavirus outbreak too, Nimalachandra has taken the lead. “In the entire Monaragala district, the workers of the two factories were the ones to get the COVID-19 vaccines first. We produced our own hand sanitisers and adhered to all the health guidelines. We gave them the masks and made facilities to isolate anyone who was suspected of being infected.”

Bolstered by the success at Pelwatta and Sevenagala in the past two years, Lanka Sugar will add a new factory under its wing shortly. “We are undertaking a third facility, also in the Monaragala district called the Weli Oya Sugar Factory in the Tanamalwila divisional area. There is a lot of unutilised land with no forest cover hence there will be no harm to the environment. The villagers grow only seasonal crops and have no real livelihood. We will utilise around 100 hectares for the factory, planting crops and other needs,” he said.

Cabinet gave approval in January to the proposal by the Minister of Plantation to implement this project.

In the pipeline also are plans for two bio fertiliser factories as well as revamping the facilities at Pelwatta and Sevenagala. This has meant reinvesting some of the profits to develop the factories and giving more benefits to workers.

“Even though we made Rs. 1.6 billion in profit, we could have made it Rs. 3 billion but we reinvested about Rs. 2 billion from the profits for workers welfare, giving them permanent employment, bonuses, etc. Also, for this year we have budgeted Rs. 400 million to upgrade our factories. A solar power project too will commence this year aimed at providing 10 megawatts to the national grid.

Nimalachandra said that many have contributed to the turnaround at Pelwatta and Sevenagala and credited State Minister for Development of Minor Crops Plantation including Sugarcane, Maize, Cashew, Pepper, Cinnamon, Cloves, Betel Related Industries and Export Promotion Janaka Wakkumbura who has supported the company in all its plans.