Saturday Feb 14, 2026

Saturday Feb 14, 2026

Thursday, 2 July 2020 00:02 - - {{hitsCtrl.values.hits}}

University of Moratuwa Department of Integrated Design Head Sithumini Rathnamalala

Vindya Jayawickrama – COSTI, Ministry of Technology and Innovation

Prof. Hiran Amarasekera – Department of Forestry and Environment, University of Sri Jayewardenepura

Henry W. Cave in 1980 has written quite interestingly on Moratuwa carpenters and their skills – “The people who live here are carpenters. Using their own carpentry tools, their hands and fingers work perfectly. They are skilled workers and make beautiful carvings. Some of their cabinets are excellent. Thousands of tables, chairs, couches and beds are made under the sheds of coconut palms on the banks of the beautiful Moratuwa Lagoon.”

Today the same way of writing to be expected over the products from this area I am sure we all know the answer. The beautiful lagoon is also no more, quite polluted and more mosquito larvae than fish that once it supported. Still the area supports the same livelihoods but the glitter is gone and is in need of attention and most definitely innovation.

COVID-19 did not stop us from attending to research projects and examinations and it was an illuminating two undergraduate research projects that I had the pleasure of examining from the University of Sri Jayewardenepura carried out under the supervision of Prof. Hiran Amarasekera and Dr. Priyan Perera of Department of Forestry and Environment. The research projects of H. Himandi and D. Liyanage were concerning the Moratuwa wood working industry and the information and analysis contained within are very useful – if one wants to understand and make a meaningful change.

The fact what Moratuwa has as a wood working cluster is unique and has the potential to upscale it as an economic hot spot plus a special tourist spot. Tourism? – Just see how NHK the Japanese television showcases the traditional craft and craft places. Furthermore Moratuwa has the potential to be a demonstration zone of a circular economy via industrial symbiosis in practice, if steps are taken with understanding.

As the findings showed it is alarming that education and skills development is missing in action as the industry progresses at Moratuwa even though the area is surrounded by two universities and a number of technical and vocational institutes. Almost 81% of those currently employed had acquired skills from only on-site training.

Timber brought in is turned into simple commodity items and there is not much design thinking applied. Considering exports from wood working the most demand appears to be on brooms and brush handles and that too to India. The danger is as times moves on, the younger generation may find more solace in three-wheelers than in sharpening a craft that has given Moratuwa the name as timber city of Sri Lanka.

It is apparent that there is no real Moratuwa timber city feeling at present as it is more the opportunity of a livelihood. I am sure that there are some seniors who definitely have the sense of belonging from what they do but the overall situation is different. Around 30-40% of the timber as logs brought in to process are lost as saw dust, wanes and off cuts and the waste is a burden. As you move around Moratuwa it is quite common to see places of disposal though there are some activities in waste utilisation.

The two research studies identified 6500 MT/month of waste coming out of 1631 industrial establishments. It is quite unimaginable why this state of affairs has been allowed to continue like this. One must place an economic value added at present targeting the physical zone and then plan out a 10x value realisation with a defined time period. Nearly 30% lost and commodity low end products beg for action.

|

|

|

|

Timber based products and applications have never actually lost their appeal and across the world this situation prevails. Swedes are quite proud of their institutions and it is they who reward the most significant discoveries with Nobel Prizes at Stockholm. One institution that stands out in Sweden is IKEA the furniture giant who came up with its own brand of product, process and business model innovation. Actually IKEA reached out in all four forms of traditional innovation models as defined in the Oslo Manuel – the standard method in measuring innovation in the European Union. The fourth innovation model is customer experience and a visit to IKEA shop is customer experience. Now all these demonstrate is a measure of innovation to timber.

Ingvar Kamprad founded IKEA when he was 17 years old and he started selling what the community wanted. It is interesting to see the name coming up with the two initials of the founder, the farm on which he grew up and the village he was associated with. Such a process has not prevented IKEA from becoming a global brand. Today we may spend millions and many a month just trying out the name! No wonder as his process reminds me of what Shakespeare said “What’s in a name”.

What matters is how you would execute and the substance of the effort and if you expect success by the name and the network that is definitely not what is important. For a 17-year-old he did carry a vision, which he articulated and perhaps still resonates and another lesson to our timber city – Why are beautiful products only made for a few buyers? It must be possible to offer good design and function at low prices.

I remember then State Minister Eran Wickramaratne writing to University of Moratuwa requesting possible action on improving the timber sector in Moratuwa. This query triggered COSTI to initiate a National Innovation Program on Timber. This resulted in a budget accepting a proposal to initiate an innovation program on timber associated with Moratuwa. COSTI designed a project with intellectual property, technology and design in mind as the way to uplift the timber sector.

The basis was value chain innovation. The program involved coupling the only academic department on Forestry and Environment in the country along with the Integrated Design department of Uni of Moratuwa – that is another one and only! Timber supply chain, quality and sustainability was the domain of USJPura Timber Process Innovation Centre. For UoM Design was the key expectation with its Timber Design Innovation Centre.

How can one turn tables?

Going back into furniture history it is well known what George Nelson the designer at Herman Miller did to the staid commoditised furniture sector in 1945 and today we all hear on Herman Miller. How can one turn tables? Design thinking once inculcated sees no limits and no one champion can exist. So let’s see how the neurons would play out locally with dice thrown in. The Mechanical Engineering at UoM is also connected as the design conversion to products needs technology upgradation and the Team Mechanical had to come up with those answers. Note that the basic skill set prevailing at present is pretty weak.

Then again after the initial activation of the project the incoming State Minister for Technology and Innovation Thilanga Sumathipala took an active and a serious interest in the project and accelerated the grounding of the project to the timber industry at Moratuwa. He came up with Moratu Lee as a certification mark call and engaged the local Vidatha centre at Moratuwa, etc. for showcasing products. That was an encouraging fast tracking the program and gave it much needed publicity plus connectivity.

The project launch of Moratu Lee was well attended and hopefully the industry is interested. Currently very few timber designers exist and the influence of local design is not quite strong. Bulk of the work in this regard is carried out by the State Timber Corporation who is also part of the program. There are a few strong local industry players in this sector but integration with different actors as one can observe with Toyota that you can observe at Nagoya is missing.

|

Moratu Lee

|

Seasoned timber is also not a well-traded commodity and the technologies deployed are not the most suitable from a sustainability standpoint. Moratu Lee has interesting prospects as it carries the opportunity of creating an identity with a geographic location and it is in this location that we have 1,500 plus enterprises of different scales all of whom called Moratuwa as their home and some for over a century.

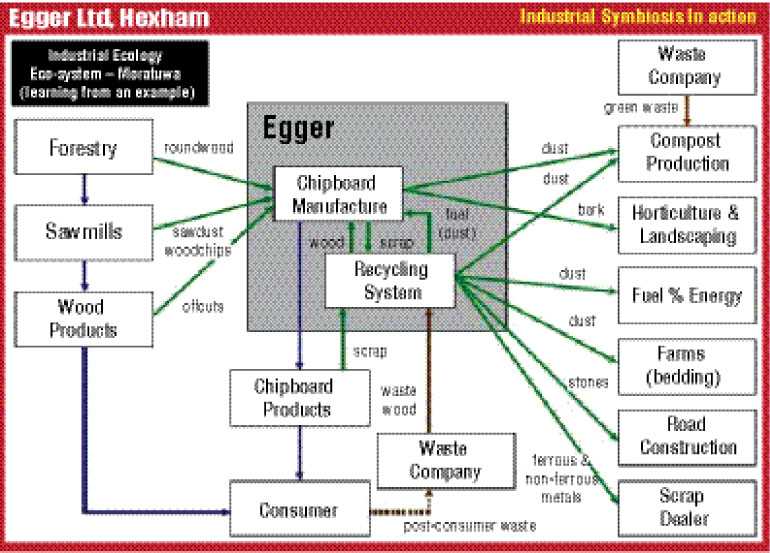

One experience that is possible from IKEA exposure is the ability to select and assemble by you. IKEA probably took the plug and sit model to a new level. There may be an element of disposability when pushing sales yet there is value in this format. Today we do have circularity introduced into IKEA operations. However the opportunity to go circular across Moratuwa can be explained simply as follows. As it had been identified there is significant wastage. It is an imperative that this waste is minimised however the waste should not be a problem if there are mechanisms located on site ready to use waste as resource.

When a collection of such institutions gets co-located the result is the development of industrial symbiosis opening up. This is also mimicking nature as in nature there is no such thing as waste and that is the template that the new economy has to model itself if one is to make any progress. Otherwise we would be treading an unsustainable pathway.

To transform Moratuwa in such a way, enlightened investors, financing agencies and even politicians are necessary. The basis for triple helix model of development as far as the industry is concerned has been initiated. The industrialists of all levels should understand the opportunities if they act differently. If this meeting of minds could be achieved what is achievable would be of very high value.

Moratuwa waste - much waste is generated and is a significant burden

Circular economy possibility – Lesson from UK

Presentation of Moratu Lee to the President

Moratu Lee – Mark presentation

Project launch at Moratuwa

Project launch at Moratuwa