Sunday Feb 22, 2026

Sunday Feb 22, 2026

Wednesday, 8 February 2023 00:20 - - {{hitsCtrl.values.hits}}

PPL to replant further 1,050 hectares of rubber and 450 hectares of tea by 2027

PPL has a network of rubber nurseries producing over 300,000 plants annually

PPL has injected over Rs. 679 million into tea replanting across 223 hectares during the last 6 years

The newly constructed Rothschild Estate Tea Factory with state-of-the-art machinery

PPL to open Rothschild Tea Centre for foreign tourists who travel to Little England, Nuwara Eliya

The company invested over Rs. 75 m each year for rain-guarding rubber trees

PPL in collaboration with RRI introduces ‘Slow Release Fertiliser Application’ designed to gradually release nutrients to the plant over an extended period

In an industry with a legacy of over 160 years, Regional Plantation Companies (RPCs) have been finding novel and innovative ways to keep the industry afloat amid change. Following its acquisition by Damro Group in 2017, Pussellawa Plantations Ltd. (PPL) has been among the most progressive in its investments in replanting, factory modernisation, innovation and diversification of its product portfolio to cater to changing consumer demand, mainly in tea and rubber.

Since the Group’s entrance into plantation management, the company has become one of the country’s two major producers of tea and rubber, with an employee strength of over 10,000 employees, among which over 6,000 are employed under PPL.

Today PPL is gearing up for a new phase of growth. In addition to securing the Forest Stewardship Council certification (FSC) for some of its prime rubber properties, the company has also obtained the Rain Forest Alliance (RA) certification for its upcountry tea estates, which shows the company’s commitment and responsibility towards sustainability. Furthermore, most recently, all PPL tea manufacturing facilities have obtained the ISO 22000 Food Safety Management System certification.

Improving productivity and sustainability

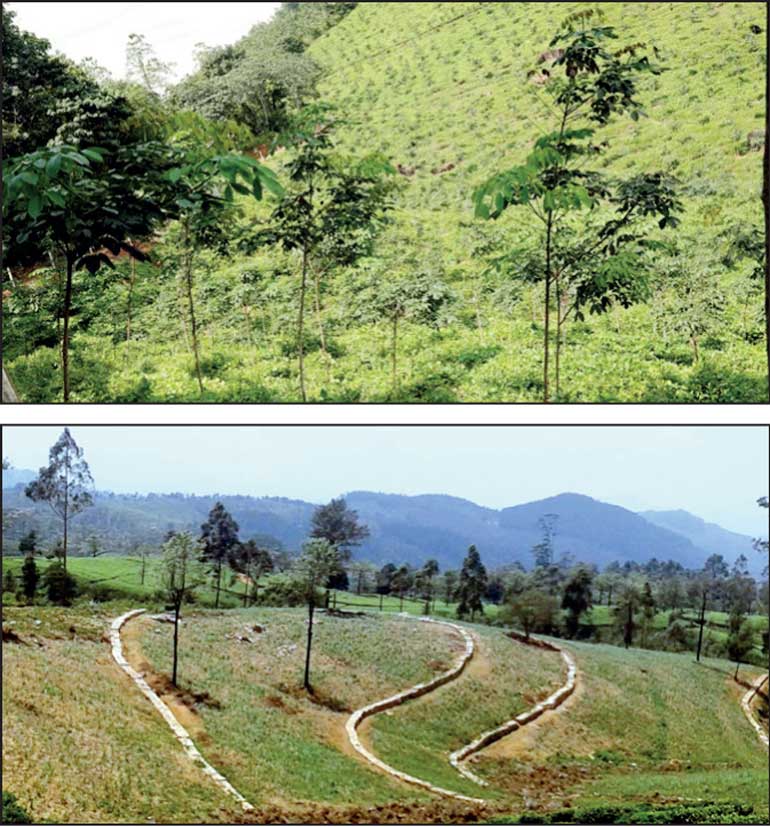

Replanting and rehabilitation of tea and rubber determine the industry’s productivity and sustainability, bringing much-needed foreign exchange to the country annually. Keeping this in mind, a strategic management decision was taken to prioritise replanting across all estates under PPL since 2017.

With the rubber extent spanning 4,780 hectares, the company has invested over Rs. 715 million to replant a substantial hectarage of over 910 hectares over the past six years. A further sum of Rs. 1,150 million will be invested in the next five years to replant a further 1,050 hectares of rubber which is expected to boost the crop volume and the future yield per hectare of the company.

“The priority that we have given to replanting has already enhanced yields to over 1,200 kg YPH which is well above the national average for rubber,” PPL Chief Operating Officer – Rubber Manoj Udugampola said.

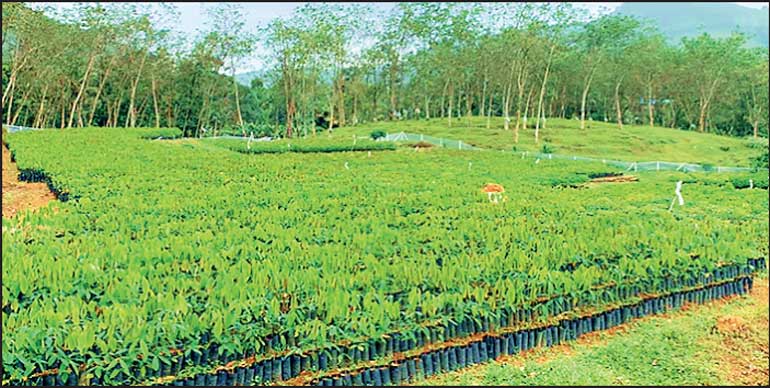

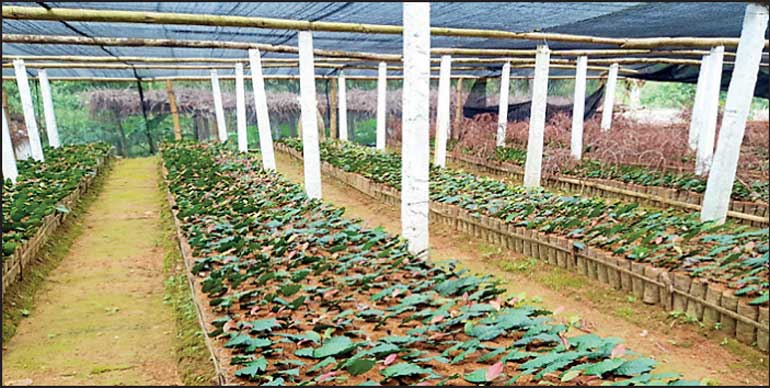

In order to support the company’s ambitious rubber replanting program, PPL has its own network of rubber nurseries producing over 300,000 plants annually at Elston, Eheliyagoda, Pussella, Salawa and Siriniwasa Estates.

“It is envisaged to plant another 235 hectares of rubber in 2023, using our own high-quality planting material. Rubber replanting is a very important exercise which is a key requirement in maintaining the viability and sustainability of the rubber industry, given that the life span of a rubber tree is around 30 years old. If we are to be competitive in the global market, our yields have to be over 1,500 kg per hectare.”

Importance given to field development and adaptation of good agricultural practices

As a thrust to achieving its targets, specifically in rubber replanting, PPL in collaboration with the Rubber Research Institute (RRI) has introduced new and cost-effective methods to enhance productivity and increase yields.

In order to overcome the shortage of skill tappers and to improve productivity, the Low-Frequency Tapping System (LFT) has been introduced across its estates in the last five years.

“The results of LFT has been outstanding. In just under four years, we have seen an increase in tapper productivity by 20% to 25% compared to the conventional tapping methods resulting in worker productivity increasing from 7 kg to 10 kg per worker. This has provided them with an additional income,” Udugampola said.

The company also invests over Rs. 75 million each year for rain-guarding rubber trees to aid LFT activities and to maintain regular tapping rounds given the unpredictable, erratic weather patterns. Furthermore, rain guards are fixed to all tappable trees on estates except in the areas which are earmarked for uprooting. This adds additional tapping days and increases worker productivity, especially during the rainy season.

One of its landmark collaborations with RRI, is the introduction of the ‘Slow Release Fertilize Application’ in immature rubber areas. This method is designed to gradually release nutrients to the plant over an extended period.

“The pilot project conducted on our estates in 2018 have shown that the application of Slow Release Fertiliser is an effective method, especially amidst a fertiliser shortage and increased cost of production. We are happy to note that this method is replicated in many RPCs as it only requires half of the normal requirement of fertiliser,” Udugampola noted.

In the search for new opportunities

Currently Pussellawa plantations Ltd manages over 2600 hectares of well-nurtured tea. In a bid to develop its upcountry and low-country tea estates, PPL has injected over Rs. 679 million into tea replanting across 223 hectares during the last six years, and it has also planned to invest a further Rs. 1,800 million to replace 450 hectares of all low-yielding and old seedling tea fields within the next five years. The company produces over 750,000 vigorous high-yielding plants on an annual basis internally to cater to the accelerated replanting program. The company also has a mass-scale organic fertiliser production unit which has already produced over 6.5 million kg of compost during the last five years solely for its plantations to rehabilitate the degraded soil conditions in its estates.

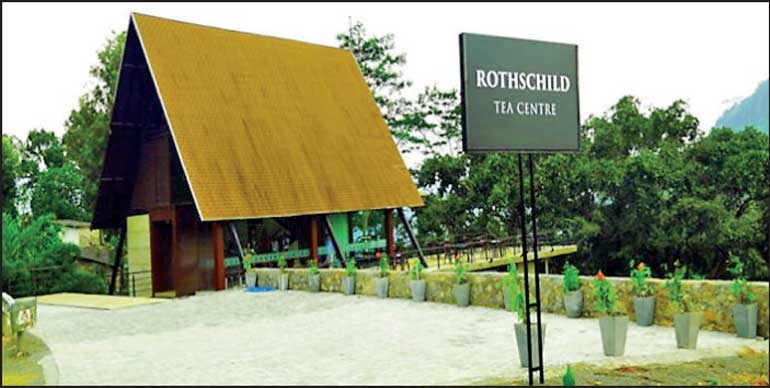

Furthermore, PPL constructed a new state of art tea factory with an investment of over Rs. 400 million at Rothschild Estate, Pussellawa, enabling the company to handle enhanced quantities of its own crop internally with a better sales average. Rothschild estate, which has a rich history of over 180 years, came into being when Worm Brothers bought tea seeds from China and formed a small garden at Pussellawa, Condegalle – possibly the oldest tea cultivation in Sri Lanka.

“We have already managed to recover the initial investment made from the state of the art factory with the profits made so far. We are now in the process of opening a new Tea Centre attached to the new factory with a scenic view of the lush tea gardens to attract the local and foreign tourists who travel to Little England, Nuwara Eliya,” PPL Chief Operating Officer in charge of Tea Chaminda Senaratne said.

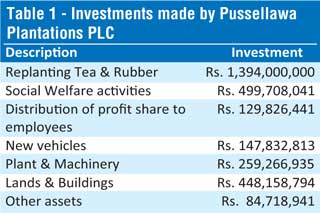

The company has made significant investments exceeding Rs. 2,964 million during the last five years across all sections of the company boosting its future sustainability.

“With these investments in place, it is our hope that we usher in a new era of prosperity in Sri Lanka’s plantation sector. This is only the start for Pussellawa Plantations as we continue to bring in new innovations and pioneer new methods in sustainable agricultural practices, especially in tea and rubber. With our capable and skilled employees, moving forward we will continue to explore and invest in all viable means for enhancing productivity, while sustainably diversifying into crops and lines of business that offer the highest return, and creating further opportunities for vertical integration and value addition through synergies generated across the Damro Group,” Senaratne said.