Friday Feb 20, 2026

Friday Feb 20, 2026

Wednesday, 18 January 2017 00:00 - - {{hitsCtrl.values.hits}}

Many companies around the world adopt the Six Sigma Methodology in an effort to improve any area. Six Sigma, a powerful breakthrough in business improvement strategy has its roots in the 1980s; beginning from Motorola, and has since been implemented by a number of world class organisations.

Today, Six Sigma has evolved into a more business-management philosophy focused on meeting customer requirements. Caterpillar Inc. embraced Six Sigma in 2001 ingraining it in all aspects of the business with Dealers too taking on the commitment and reaping its benefits.

As the country’s sole authorised dealer for Caterpillar, United Tractor & Equipment Ltd. (UTE) uses the synergy of Caterpillar best practices to achieve excellence. UTE also practices Caterpillar’s continuous improvement methodologies such the Caterpillar Production System (CPS) which uses tools including Six Sigma.

Embracing and deploying Caterpillar Six Sigma culture across the organisation has enabled UTE to gain a formidable competitive advantage that enhances the value of its products and services.

Explaining the company’s Six Sigma approach, Tharaka Dayabandara, UTE’s Caterpillar USA certified Six Sigma Master Black Belt, said: “As a breakthrough management strategy it uses statistical tools for its data driven decision making approach in the process of continuous improvement, focusing on excellence to do things better.”

Master Black Belts are Mentors of the Six Sigma process, Black Belts and Green Belts generally drive and run projects with relevant stakeholders and Subject Matter Experts (SMEs). “It is not just about using statistical tools and being mathematical about it. It is about continual improvement with purposeful change,” he noted.

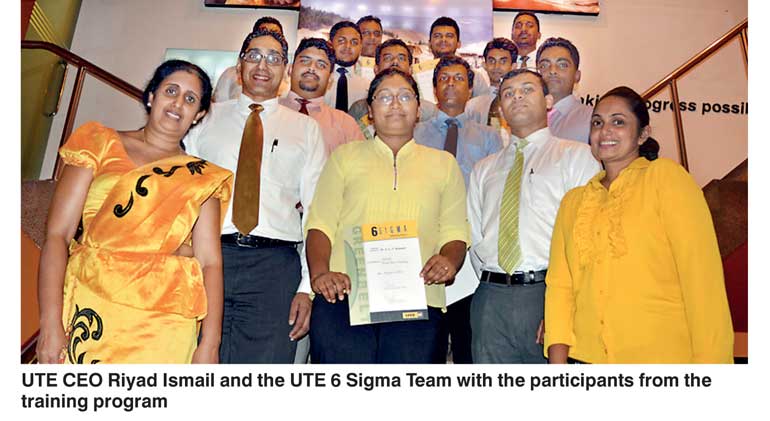

The Six Sigma approach is embedded companywide at UTE. “95% of our executive staff; senior managers, managers, executives are all Green Belt certified,” Dayabandara added. Leveraging on its learning and promoting its benefits, UTE recently organised its first ‘Six Sigma DMAIC Green Belt Certification’ program for a few of its customers to provide local corporates insights into the implementation of the Six Sigma philosophy.

The ‘DMAIC’ improvement cycle is the core tool used to drive Six Sigma. DMAIC is an acronym for Define, Measure, Analyze, Improve and Control; which are the phase of Six Sigma improvement cycle. The certification covers a range of content including fundamentals of Six Sigma and its use during the DMAIC process. Participants are also guided to identify root causes, propose solutions to an identified problem in their respective organisations, and implement change.

“A key element in Six Sigma is to effect a change in the culture of an organisation. Six Sigma professionals always act as change agents and are closely knit with the culture of the organisation. Through Six Sigma UTE has achieved certain advantages and we wanted to promote the methodology,” he said.

This program would be ideal for Senior and Middle managers, and planners engaged in strategy and operations. Upon successful completion of the one-month program participants are awarded the ‘Six Sigma DMAIC Green Belt Certification’.

“This is much more than another theoretical qualification. Six Sigma professionals can implement their learning, showing concrete organisational benefits,” said Riyad Ismail, CEO of UTE. Though Six Sigma is practiced and followed among some local corporates, opportunities for certification are few. “Over the years, Six Sigma has helped improve UTE and we believe the methodology has value for other companies,” Riyad added.

During Six Sigma training program, participants are challenged to take on a project in their own organisations; to show improvements in the process. Having successfully concluded the inaugural Six Sigma Green Belt Certification program, UTE looks forward to train interested participants. Each intake is limited to only 15-20 participants to provide ‘hands-on’ learning where students are instrumental to key concepts and skills put into immediate practice. Next Training program is scheduled to be in March/April 2017, you may enquire further details of the program on [email protected].