Thursday Feb 19, 2026

Thursday Feb 19, 2026

Thursday, 10 May 2018 00:00 - - {{hitsCtrl.values.hits}}

In manufacturing and in processing, we appear to have been complacent when we can import something and if dollars come in as a result. Some still appreciate when more rupees can be realised from a dollar received! It is enjoying a weakness as a strength and not really caring about the big picture but being quite content with one’s own situation.

If we do not link our small actions with the big picture, the big picture may never change in the way we aspire. We have not linked the societal transformation that has to happen and thereby the economy. The argument in this column is that industry segment of the economy can do much, much more and should be planned and executed in that manner.

An industry is not purely a job-producing machine and the emerging Industry 4.0 actually may be quite different! It is the overall transformational effect that is possible with dynamic industry sector that planners should understand.

BASF and chemistry

In my last column (http://www.ft.lk/columns/Exporting-bras--with-imported-fibre-/4-654002) I gave an example of a process industry in Germany, now a global giant, that transformed an economy working in tandem with other players.

The conversation in that could not be concluded as the pictures associated were not in the column and I think the impact went missing. Hence this continuum. I took the case of BASF (Badische Anilin & Soda Fabrik AG) where chemistry is life!

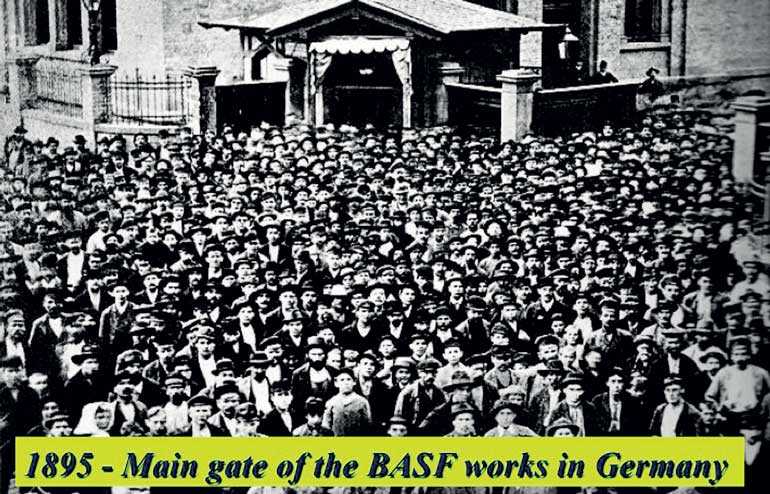

In the published history of BASF ‘In the Realm of Chemistry,’ the book traced the history and the development of BASF. A couple of interesting pictures from the journey of BASF to me were quite significant and I specially viewed them when I first saw them with much interest as I sensed so much with those two pictures.

One picture showed the entry to its Ludwigshafen chemical industry site where the picture from 1895 can almost be somewhat similar to an entrance to a Sri Lankan apparel factory zone today but with a gender difference – walking in foot and crowding at the gate to enter.

I know that a direct comparison to today’s apparel factory entrance is not exactly right as buses do play a role and the gates are different, but I hope the reader gets the point going beyond the direct literal interpretation. The problem is some do take the direct literal interpretation and get into an interpretational mess.

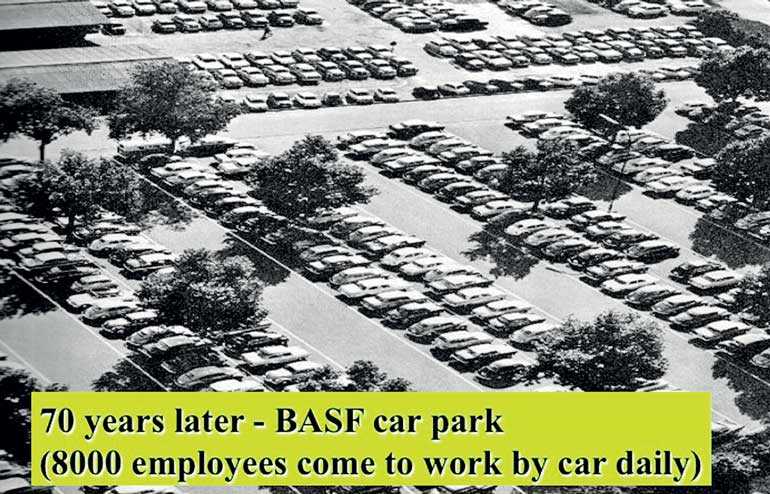

The other interesting picture is when the book shows one of the car parks of BASF 70 years later and claims that ALL 8,000 employees come to work by car daily. Sri Lanka has though graduated from a LDC to a Middle Income country has not been able to do much change to the Gini coefficient at all and that is a poor showing.

It has been shown that Sri Lanka for most of the time since independence has had the value of this coefficient within 0.4 and 0.6 – inside the range that is equated with high inequality. As per economists this is clear and from a non-economist then we are still having rich getting richer and poor poorer. In the economic development process equity has to be addressed and growth is not the only parameter.

A simple parallel is that clean streets and cities are not exactly clean if there are 260 solid waste dumps dotted across the island. The waste management story is complete when visual cleanliness comes with the absence of dumps. Social inequalities and collapsing dumps mean that we have not addressed the issue holistically.

Transformation for all

Now the transformation of BASF had been for ALL. BASF literally supported Germany to change as well by becoming a global giant and still continue to do so by being an important company in Europe’s No. 1 economy – an economy built on manufacturing and processing.

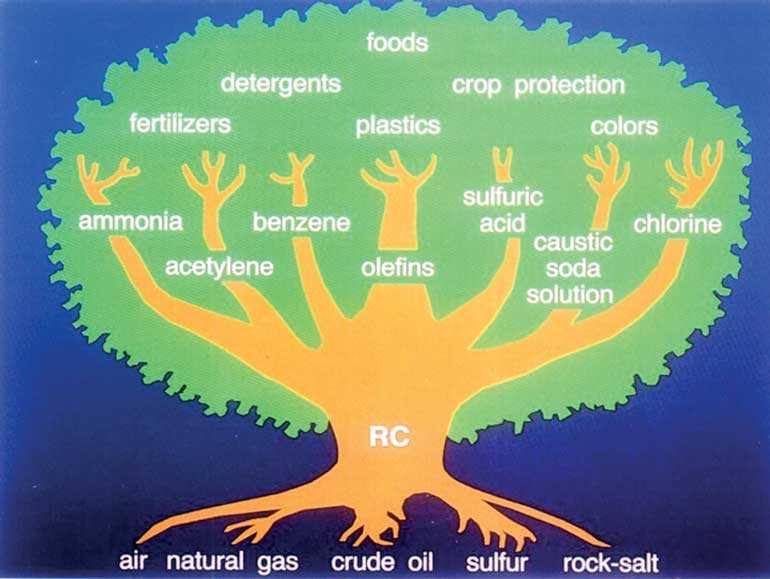

It is also interesting to note that the success of BASF it owes to five chemical raw materials – salt, air, sulphur, natural gas and crude oil. Now Sri Lanka can get salt much easier as we have access to more sea water than water and Germany has to mine its salt and we have two of these raw materials in abundance. However, it is not necessary to have all these five to speak of industrial growth nor these as the sole five that can do the trick.

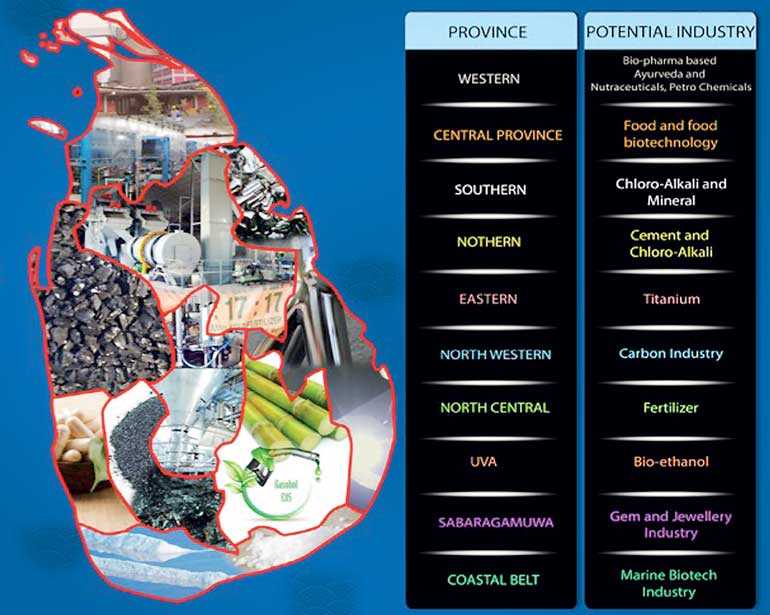

Consider the strengths of Singapore and Israel in the water industry, when they engaged developing processing for sea water and reclaiming water for their own benefit but now paying global economic dividends. We can view province to province in Sri Lanka to think of a major process industry for a province, which can uplift the province if carefully nurtured. Then the developed major industry should not have only benefits for the province but the province in which it is based necessarily the first and a continuous beneficiary.

What is at times noted in Sri Lanka is as we planned with much less local benefit in mind, the local landscape most of the time is left with serious environmental pollution and few lower level job opportunities. How many times we have witnessed locals rising out against manufacturing concerns and with the political system behind them as well.

A couple of examples of such failures, alum plant at Ranala, gloves factory at Waliweriya, and caustic soda at Paranthan. If one take some time off to analyse these cases they should yield us some rich lessons. Many factories that have been established endure their existence rather than seen as shining examples of process industry.

Where is the equivalent of at least one mini-BASF in a Sri Lankan context? Where is the vision or an intention similar to that displayed by Friedrich Engelhorn? A set of suggestions mapped with the Sri Lankan provinces conceptualised and submitted by COSTI – as K.C. Somarathne has indicated as an expectation in his column (http://www.ft.lk/columns/Rubber-to-erasers-and-value-addition-to-local-produce/4-654517) is presented here.

Considering the magnitude of the intention I must state that this can be discussed in depth and this may not be the space for that. However to press home the logic of the suggestion I do hope that some discussion gets ensued with the figure in question. Please note that the suggested list is a process industry option, which matches to my way for our economy.

The list indicated perhaps belongs to an earlier era than today as some scale is expected and necessarily has to be there to have an impact. We are increasingly entering into an era where scale of that nature is not what is exactly needed. However I can state that within the process industry there is a movement towards process miniaturisation and as such actually Sri Lanka need not take a lesson from the factory images of current Ludwigshafen site anymore.

Today different types of capital are more valued. However, what was observed with BASF is that BASF ensured from the very beginning the value of intellectual property. In fact Caro- BASF’s first Director of Research, had much influence on the German Patents Act of 1977! This is an area where we are yet to address in a satisfactory manner though some efforts are currently underway.

Our economic planners should be prepared to value manufacturing and there is still the space for a Sri Lankan process industry. We can process our way into a better future – Definitely!