Friday Feb 20, 2026

Friday Feb 20, 2026

Tuesday, 17 December 2019 00:00 - - {{hitsCtrl.values.hits}}

Global giant in pump and water technologies, Grundfos is leading its transformation through the fourth industrial revolution.

|

Grundfos Global Business Director (Machining Industry) Eric Lai |

“Besides protecting our core pump business, we will in the coming years add layers of system solutions, digital offerings and services – and ultimately deliver water-as-a-service business models,” Grundfos Global Business Director (Machining Industry) Eric Lai said recently to a group of visiting journalists from Asia in Singapore.

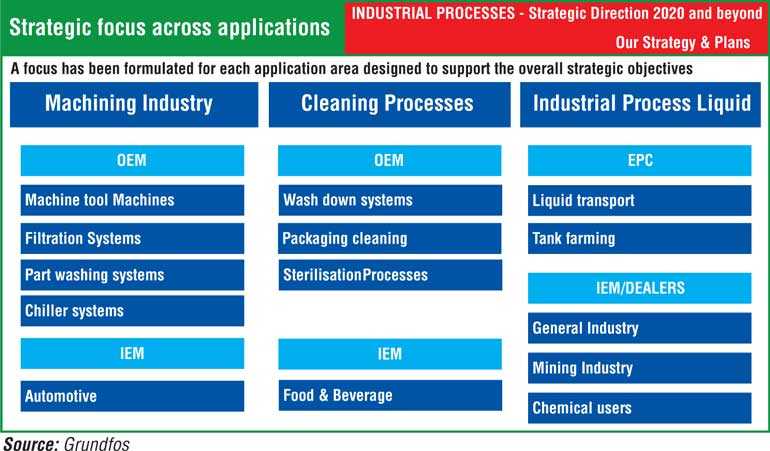

Grundfos supplies a broad range of pump systems and solutions for industrial processes, industrial utilities, system builders and OEMs. Grundfos provides pumps for a wide range of industries including food and beverage, agriculture, maritime, pharmaceutics, manufacturers, and machine-linked industries.

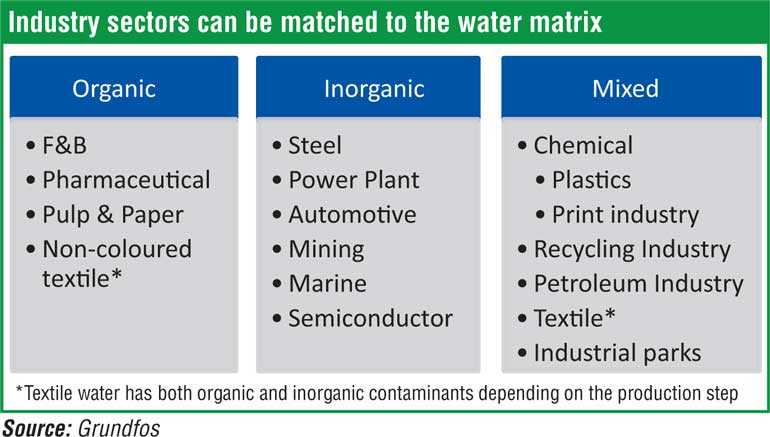

Overall, Grundfos has divided the industrial market into three application areas: water reuse, which includes water transport and treatment; temperature control, which consists of industrial heating and cooling and industrial processes, which include pumping applications inside the production process. Talking of industrial water re-use, Lai said at industry level there are many sources of water such as boiler blow down, cooling water dump, washing water and unused process water. And this water can be recycled for re-use of cooling, W&C, firefighting, irrigation, boiler process, etc.

It was pointed out that in managing water resources industrial units face several challenges. Firms are legally required to reduce wastewater as well as pollutants in the wastewater stream. From a cost perspective the need is to reduce intake of freshwater, reduce cost for wastewater release, process water preparation.

Nevertheless, industrial units are impacted by conservative thinking and fail to realise the benefits of effective solutions to manage water. “The tendency is to treat water solutions as a capital expenditure instead of operating expenditure,” he said.

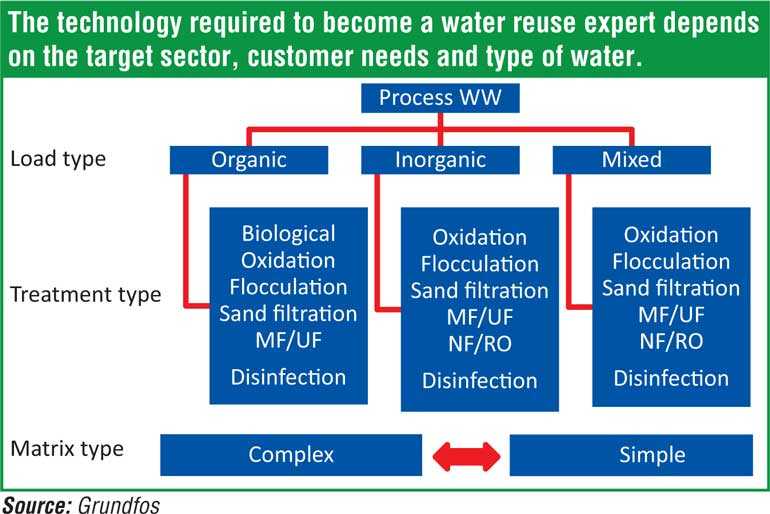

According to Grundfos, the technology required to become a water reuse expert depends on the target sector, customer needs and type of water (refer to graph). He said Grundfos portfolio already serves the applications required for both industrial process water and wastewater. They include pressure pumps, transfer pumps, dosing pumps, chemical disinfection, mixer controls, sensors and drives.

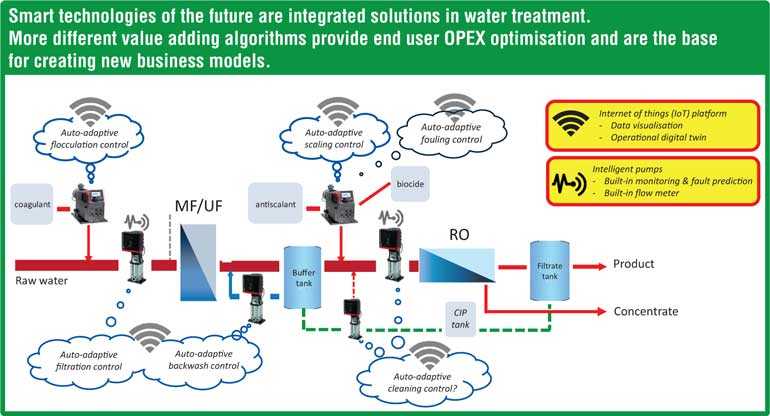

He said Smart technologies of the future are integrated solutions in water treatment. More different value adding algorithms provide end user OPEX optimisation and are the base for creating new business models.

Grundfos has offered solutions to diverse industries. Some of the examples are Smart Brewery involving a connectivity project for an international brewery. International brewery and Grundfos partnered to startup a Smart Brewery project. The scope now is focused on the cloud solution – condition-based monitoring pending.

Grundfos sees GCM as a significant growth enabler within temperature control and iSOLUTIONS offerings. At present trials and pilots with potential applications are on-going.

The project also involves evaporation cooling tower featuring iSOLUTIONS.

According to Grundfos direct benefits include: Changing from non-controlled cooling tower to

controlled pump and fan: ~12% less OPEX; water evaporation reduction using iSolutions: ~20%

less water use; optimised operating conditions with stable temperatures; lower CAPEX / OPEX if iSOLUTIONS retrofit and Less components and simpler installation for OEMs.

Another aspect is on heating, with steam boiler applications featuring iSOLUTIONS. Aim is to provide distilleries access to live boiler consumption data. Benefits include: Optimised operating with stabile tank-levels; gas savings at full-load 18 ton/h = 9%; gas savings at part-load 5-18 ton/h = 1.4% and significant OPEX reductions.

Another project showcased by Lai was specialised cleaning in the food processing industry targeted towards the increasing demand for food safety.

It utilises the full potential of Grundfos iSOLUTIONS, during a continuous process of developing application specific features and functionality in the MGE motors and CR product program.

Grundfos is the sole supplier of highly customised, high performance pumps for the top 10 OEMs located in Northern Europe with worldwide presence.

Product program is developed in close cooperation between Grundfos sales staff, industry application team, CR-CSU team, and the OEMs sales and technical decision makers – over the past decade.

Based on the success Grundfos is supporting new customers outside Europe; supporting connectivity demands by trendsetting customers (Lagafors, Foamico, System Cleaners); testing new functionality and algorithms – cavitation and dry run protection, stabilised pump curves and flow estimation (Lagafors); Upgrade of MGE motor firmware with new demanded functions; working on new algorithms supporting the digitalisation agenda (change in operation pattern, damaged components, leakage, controller stability).

As part of its innovation, Grundfos is digitalising processes in the industry as well. The Grundfos Condition Monitor ‘6th Sense’ has features such as alarm limits, user interface on LDU and GiC, and PCTool. It has conducted 11 internal field tests and 15 externally.

It is also applying iSOLUTIONS to Grundfos own production, learning how the products are operating during a production week. It is examining whether any ‘iSOLUTIONS’ that Grundfos customers will benefit from especially on water and energy saving.

Founded in 1945, Grundfos is the world’s biggest manufacturer of water pumps supplying over 17 million units annually. It has nearly 20,000 employees in 56 countries. In Asia, where Grundfos is marketed in nearly 20 countries, it is the leader, and solutions to industries account for over 40% of its regional sales.

To acquire new businesses and serve customers in Sri Lanka, Grundfos works with four partners Hayleys PLC Group’s Hayleys Aventura Ltd. for commercial building services, Sierra Engineering and Construction Ltd. for water utility projects and public tenders, Analytical Instrument Ltd. for medical, analytical and agricultural sectors, infrastructure development, and solar therm.

Among Grundfos’ recent milestone projects is the 47-storey mixed development Colombo City Centre, for which it provided SEV wastewater pumps and hydro MPC booster stems for plumbing and sanitary applications.

Other notable projects handled by Grundfos includes pressure boosting and wastewater solutions to Coca Cola plant in Biyagama, the Unichela plant in Panadura and the MAS Intimates in Ratmalana, chilled water circulation and delivery and automated chemical dosing water intake for Unilever for its plant in Horana, and the water supply project in Galigamuwa for which it provided drainage pumps, suction and water pumps among others to enable water treatment and transmission, and dry zone water supply and sanitation in Mannar.

Focus in Sri Lanka includes building services especially new projects offering booster system, wastewater transportation and fire pumps package for hotels, mixed development office and condominium and government buildings. Under industry booster system needed for production and waste water handling from factories discharge as well as fire pumps. Industries include food and beverage production, apparel, tyre plant, and breweries.

In water utilities Grundfos is focused on water treatment and distribution plans and more recently flood control pump stations. Equipment includes gas chlorination, dosing process, distribution pumps, treatment process pumps, and propeller pumps.