Monday Feb 23, 2026

Monday Feb 23, 2026

Thursday, 28 December 2017 00:00 - - {{hitsCtrl.values.hits}}

By E. Weerapperuma

The collection of garbage and its disposal has become a nuisance and it is turning out to be a perennial problem from the very recent past.

We read in the print media or listen to news telecast or broadcast about what efforts are being made to minimise its impact and we are assured slowly but surely that a lasting solution to the mind-boggling issue would be found.

We also come to know that some local groups both state and private concern, had taken steps to join hands with international organisations to see an end to this massive collection of garbage.

At a recent visit to the Appropriate Technology Research and Development Centre (ATRDC) Pannala, Kurunegala, made by a group of socially conscious people, they inquired whether the Centre has a solution to the ever growing garbage problem the people face, and the answer was very positive.

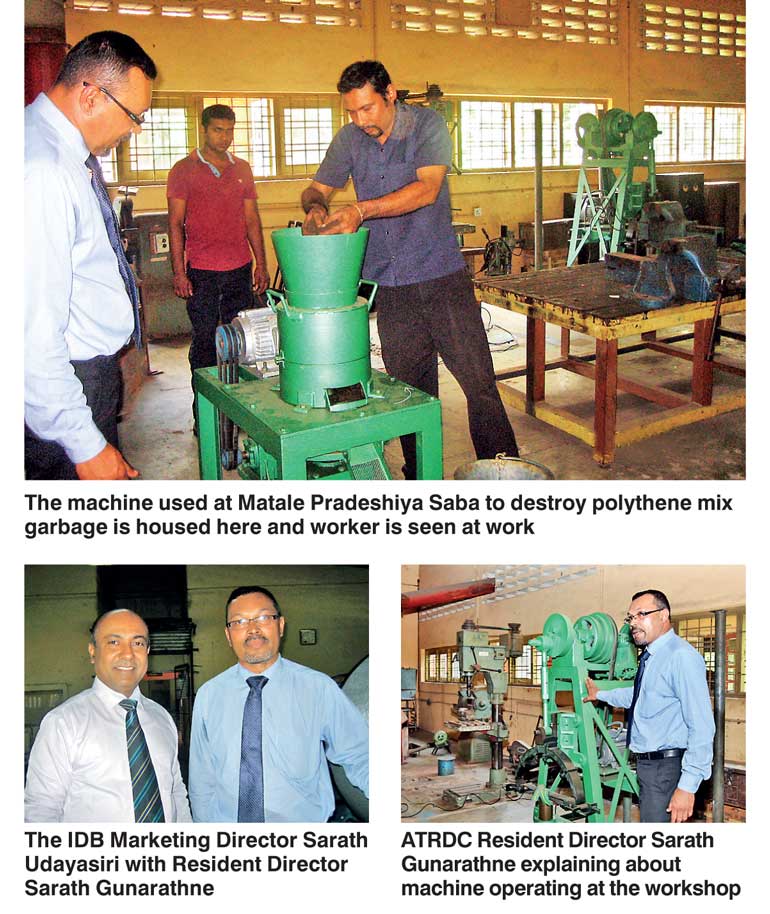

In fact, the Centre has designed and manufactured an insinuator, a machine, a complex pelletizer with three chambers for the use of Pradeshiya Sabha, Matale. Within this machine one could find, the press, burner and pelletizer.

When inquired the position of the machine, the officials of Matale Pradeshiya Saba responsible for the operational aspect of the machine told the media that the machine got manufactured with the approval of relevant authorities including the Central Environmental Authority, and was still functioning well.

It is the one and only machine so far manufactured by the ATRDC – Pannala with the approval of the Central Environmental Authority as suitable to destroy polythene evading any health hazard as a result of releasing the gas above 60 feet from the ground level.

Speaking to the media at the site, Resident Director of the ATRD Centre, Pannala, Sarath Gunarathne said, the Centre manufactures such machines on request. They are told that similar machines would be manufactured if there is a demand with the positive results gained by the Matale Pradeshiya Saba at a very affordable price to the institutions keen on using such machines to combat the rising problems mostly owing to the fact of the presence of polythene.

The Appropriate Technology Research and Development Centre (ATRDC) Pannala, Kurunegala, was established on the basis of a Technical Cooperation Agreement between the Sri Lanka Government and the Japanese Government, 33 years ago.

The agreement on cooperation, was jointly implemented by the Japan International Cooperation Agency (JICA) and Industrial Development Board of Sri Lanka (IDB) a statutory Board, under the then Rural Industrial Development Ministry.

The ATRDC comes under the IDB, Engineering Division, and has been in operation from 16 February 1985, and it will chalk 33 years of service to the nation, by next February.

While the Sri Lanka Government contributed towards this project to the tune of Rs. 9 million, by the end of the year 1986, the Japanese Government made its contribution for the success of the project in the form of providing experts, counterpart training, machinery and equipment to the value of $ 1.9 million by the end of May, 1987.

The sole purpose of this project was to help the rural sector develop through Appropriate Technology (AT).

The appropriate technology is considered the most suitable and affordable for rural sector small and medium scale industries. The AT concept includes the usage and production of specific equipment as well.

The Centre commenced operation in the year 1983 with the arrival of the Japanese experts to the country. The aims and objectives of the Government was to see that the rural sector possesses considerable potential to improve living standards of the rural polity and also create employment opportunity using to the maximum existing human and natural resources. The Government is keen to develop this sector through an integrated development of the economy without disturbing the social, cultural and ecological fabric of society.

The Centre has been doing a tremendous service to the nation in the past three decades, and continues to do so, by coming out with new machinery and other equipment to meet successfully, the challenges that prop up from time to time.

The Centre also conducts training programs in welding/fitting, low cost wooden furniture manufacturing, roller shutters manufacturing, collapsible doors, light engineering practices and provides services such as processing technology, mechanisation, production flow and machinery layout and solutions for environmental pollution.

The Centre provides services on workshop and valuation, technology transfer and advisory services, in-plant training, visits industries, assists them to improve and ensures quality products.

The Grinder, Belt Hammer, Broom Handle Milling Machine, Lawn Mower (it is attached to the four wheeler tractor to control thick grass grown), Electric Potters’ wheel, help make large clay items, Mobile Pug Mill, Bail Machine, Compost Pelletizer, Strong Crusher machine are among the machines manufactured by the Centre.