Monday Dec 22, 2025

Monday Dec 22, 2025

Tuesday, 15 May 2018 00:00 - - {{hitsCtrl.values.hits}}

The Sri Lankan economy, after a period of post-war growth, is showing signs of cooling down. The depreciating rupee and recent fuel price hikes and its ‘snowballing’ effect on cost of living is bound to impact consumer sentiment and spending, business investments and the demand for credit. The natural tendency of many businesses would be to start cutting costs and freeze development initiatives.

Research and MTI’s international experience, clearly shows that, the way in which companies respond to tough times, is what separates the ‘living’ from the ‘departed’. Most organisations tend to indiscriminately cut costs, freeze all forms of developmental work and adopt a ‘wait & see’ approach. We call them the ‘Chop & Cripple’ companies.

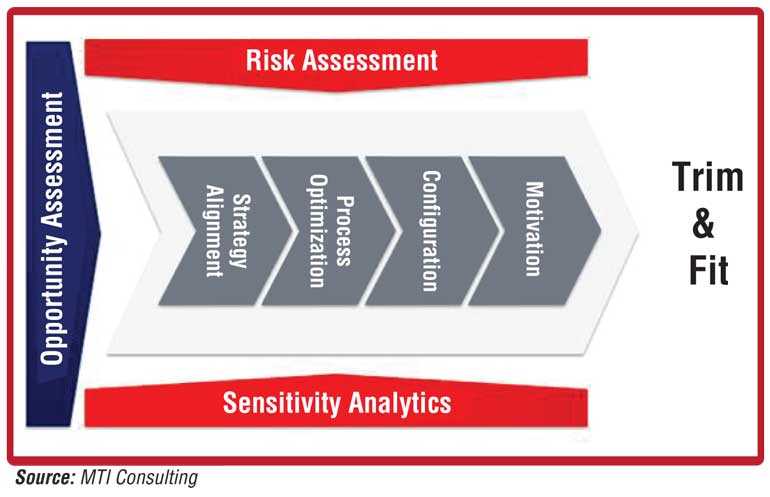

By contrast, the Smarter Companies (we call them ‘Trim & Fit’ companies), while being prudently cautious, uses the crisis period as an opportunity to critically evaluate every aspect of its Strategy, Structure, Staff and Systems, challenging every dollar and every stroke of work as to the value added. They also see the upside of acquiring low valued assets, strengthening their market position (given lower level of competitive/marketing activity) and gearing their organisations for the upturn.

6 strategic priorities to encounter tough times:

11 Questions to which you need to ‘soul search’ responses

1.How to rationalise your Customers, Product, Brands, Suppliers and Initiatives, thus removing the slack created in ‘good times’, with direct-to-bottom-line savings?

2.How to institute ROI measures for all marketing, branding, channel, sales and service initiatives, which will even permit prudent investments to grab competitor market share?

3.How to tighten the disciplines of supply chain and working capital management, with an integrated approach within the organisation?

4.How to identify opportunities for acquisition of businesses, brands, products, patents etc.?

5.How to prudently divest – any aspects arising from the rationalisation process (above)?

6.How to develop a clean-slate based lean and effective structure that will feature zero slack, minimised layers and supervision only jobs?

7.How to institute a performance based pay structure and culture – that will drive every stroke of staff work?

8.How to identify and lock-in high performers (based on the risk analysis) and how to ‘acquire’ high performers (you have tried and not been able to attract)?

9.How drive towards a lean, simple and minimalist culture, including rewards and recognitions for living these values?

10.How to develop lean and robust processes (on a clean-slate basis), thus objectively exposing the excess ‘fat’ and reducing process time?

11.How to optimise the use of cost-effective technology (including optimising existing systems), that will ensure leaner processes, cycle time and efficiency?