Friday Feb 27, 2026

Friday Feb 27, 2026

Monday, 10 May 2021 00:00 - - {{hitsCtrl.values.hits}}

Seeing the catastrophic consequences of the decision to ban the import and utilisation of conventional fertilisers in Sri Lanka, I feel obliged, as a scientist, to write this article to make the country aware of the scientific facts of plants and agriculture. This ban will create widespread food shortages in the country and sabotage our export markets in tea, rubber, and coconut, amongst other agricultural exports.

Seeing the catastrophic consequences of the decision to ban the import and utilisation of conventional fertilisers in Sri Lanka, I feel obliged, as a scientist, to write this article to make the country aware of the scientific facts of plants and agriculture. This ban will create widespread food shortages in the country and sabotage our export markets in tea, rubber, and coconut, amongst other agricultural exports.

The decision to ban chemical fertiliser importation and usage should have been given more thought considering scientific evidence rather than taking such a haphazard decision. Government must not take impulsive decisions which affect the livelihood of a whole nation and its food security. As we all are in a pandemic situation, all the nations around the globe are giving utmost priority to ensure domestic food security. I do not believe that any government will take such a decision in a crisis like this.

This decision should have been taken in consultation with scientists and agriculturists with a well-developed plan to systematically transition to perhaps a predominantly organic agriculture over a period of time without causing a famine. My scientific knowledge and research, and years of experience in the application of science in agriculture clearly show that any country needs a balanced and carefully planned combination of conventional, organic and organic-based agriculture systems.

I would like to lay out the facts and methodologies that we can employ to reduce dependency on conventional fertilisers. With the currently available technologies it is possible to gradually cut down the usage of conventional fertilisers, up to a point; the operative words being ‘gradually’ and ‘up to a point’.

If fertiliser chemistry is properly manufactured and managed, it can be utilised even to control fungal and bacterial diseases, which in turn reduces the use of pesticides. However, Sri Lanka does not have this type of technology and, as an agricultural nation, it should work to attract investors to bring these technologies to the country. Unfortunately, haphazard and arbitrary decisions like this will deter any investors coming to Sri Lanka.

Without doubt the foreign embassies in Sri Lanka must be seriously concerned by now about the arbitrariness of decision making in Sri Lanka on life and death issues, not only for investors but also for the people and their food supply. The advisors to the president must take full responsibility and accountability for this developing catastrophe.

Science of plant nutrients

Crops need 16 elements to grow and produce a good yield: Carbon (C), Hydrogen (H), Oxygen (O), Nitrogen (N), Phosphorous (P), Potassium (K), Calcium (Ca), Magnesium (Mg), Sulfur (S), Boron (B), Chlorine (Cl), Copper (Cu), Iron (Fe), Manganese (Mn), Molybdenum (Mo) and Zinc (Zn). Some crops may need Nickel (Ni) and Aluminum (Al) for specific functions. C, H, and O are taken from the air and water, hence chemical vs organic does not matter for these three elements. Plants absorb N as ammonium (NH4+) or nitrate (NO3-), Phosphorous as phosphate (PO4-3), Potassium as Potassium ions (K+), Sulfur as sulfate (SO4-2), Calcium as Ca+2, Magnesium as Mg+2, Boron as borate (BO3-3), Copper as Cu+2, Iron as Fe+2, Manganese as Mn+2, Molybdenum as molybdate (MoO4-2) Zinc as Zn+2.

Whether these elements are provided by conventional or organic means, plants absorb these elements in the same form and does not differentiate based on their origin. Conventional fertiliser inputs are available to provide these nutrients in high percentages so that the quantity of fertiliser needed is less. Some compounds can provide multiple elements as well (monopotassium phosphate can provide both potassium – 34% and phosphorous – 52%). It is very difficult to find organic sources to provide these critically important nutrients, which is the biggest hurdle in converting to organic agriculture.

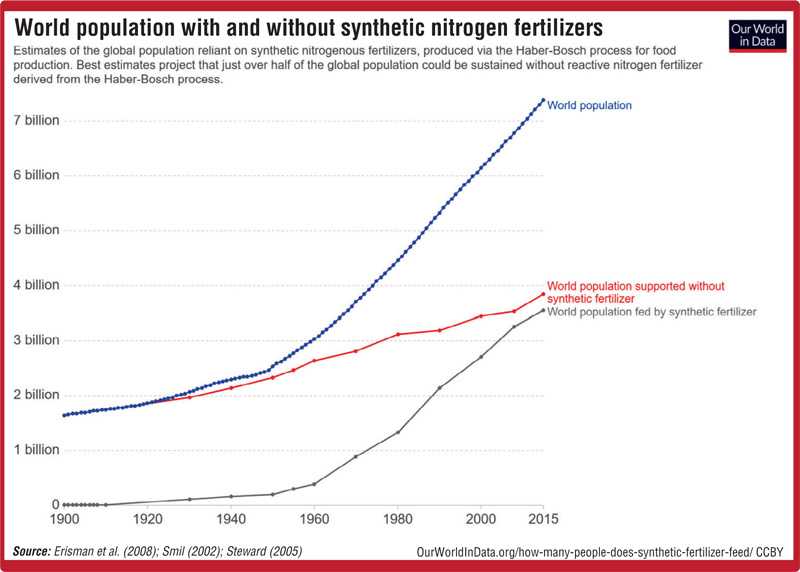

Synthetic sources of nitrogen are urea, ammonium nitrate, ammonium sulfate, diammoinium and monoammonium phosphates. Out of these, urea is the most widely used and cheapest source of N available today. Urea also contains relatively high percentage of N - 46% in it. In 2019, world agriculture consumed 198 million tons of urea. The data in the graph below shows that world population and population growth are directly related to world urea production and usage. Based on this, the world can only support half its current population without the use of nitrogenous fertiliser. To extrapolate this to Sri Lanka, only 11 million of the current population of 22 million can survive without the use of nitrogenous fertiliser.

Merits and demerits

Farming based on chemical fertilisers as well as organic fertilisers have their own merits and demerits. Using chemical fertilisers, you can precisely provide the elements required by a crop. As these elements are readily available in highly soluble forms they are easy for the plants to absorb. As formulation of chemical fertilisers are defined and controlled and are always the same from one batch to another, there is consistency in the product (similar to the consistency in pharmaceutical products), and therefore crop planning with conventional fertilisers is much easier. For almost all crops grown today it is known how much of each element is required to produce a healthy yield. Using commercial fertilisers, you can exactly provide the need of each crop.

However, just as much as a patient taking a pharmaceutical product needs to follow the recommended dosage, a farmer must follow the application rates of fertilisers. If these application rates are not followed there will be over application as the human tendency is to feel that ‘more is better’. Over application of commercial fertilisers can cause leaching of excess nutrients into ground water and other water bodies and can cause eutrophication and acidification. This can lead to health issues for humans. I am not sure whether these application rates are effectively relayed to the farmers to manage application rates in Sri Lanka. If not, this can lead to over application of fertilisers and the concomitant health issues.

Modern technologies are able to manufacture conventional fertilisers with less energy, less cost, and with more purity, while also minimising the presence of heavy metals. Green urea is an example where technology has developed to reduce manufacturing energy requirements and greenhouse gas emissions by using nanotechnology. In conventional urea manufacturing, 5 tons of CO2 will be released for every ton of urea manufactured, whereas with green urea the emissions are reduced to less than 2 tons of CO2 per ton of urea manufactured.

Organic fertilisers provide very low nutritional value to plants when compared to conventional fertilisers, and therefore need to be applied in large quantities. There are not many materials available in the world to formulate quality organic fertilisers, and extraction methods are also limited. To be certified organic, most inputs should come from certified organic sources, which further limits sources and makes them even more expensive.

As an example, conventional urea with 46% nitrogen can be bought at $ 0.88 per 1 kg while an organic plant-based product with 12% nitrogen (this is the highest % of plant-based organic nitrogen available) is about $ 12 per 1 kg. Therefore to get the same percentage of nitrogen in urea, you have to spend nearly $ 50 if going with organics. In this case, it is 50 times more expensive to choose organic nitrogen. Neither the grower nor the food consumer could afford this additional expense.

Another example is monopotassium phosphate which can give 34% Potassium and 52% Phosphorous at $ 1.65 per kg. It is difficult to find good plant based organic materials to replace both potassium and phosphorous. You can buy kelp/seaweed extract at $ 12 per kg, but it has only 16-18% of potassium. Therefore, cost is a significant factor when comparing conventional vs. organic fertilisers.

In terms of micronutrients (boron, copper, iron, molybdenum, manganese, zinc) no suitable organic sources are available, and organic systems recommend conventional sources to get these elements (sodium borate, copper sulfate, iron sulfate, manganese sulfate, sodium molybdate, zinc sulfate) only in case these elements are to be deficient in the crops. Therefore, even organic agriculture must depend on certain conventional fertilisers to provide microelements.

Due to the much less solubility and availability of elements in organics, it will be difficult to plan yield targets. Unlike conventional fertilisers, organic fertilisers can contain many unknown compounds which may accumulate in soil and plants and cause detrimental plant growth and human health issues. As they comprise of many different sources and available mainly as solids, it may not be possible to correct nutrient deficiencies quickly in an organic setting. These compounds have poor solubility. When liquid organic fertilisers are made using these compounds, there will be suspended particles which can cause fermentation in the containers, which in turn can result in bloated containers. As well, blocking of spray nozzles will always be a problem.

Fishmeal, bonemeal and bloodmeal are also considered as organic sources to provide nitrogen and phosphorous in an organic setting, if they are produced using organic inputs. As these are animal based, there are always issues related to animal diseases such as madcow disease. Importing organic inputs is neither easy nor safe, as the importing country has to protect its biodiversity. As these are plant or animal-based materials carrying microbial elements they can be a serious threat to endemic species.

A meta-analysis of life cycle assessments conducted by Clark and Tilman in 2017, that included 742 agricultural systems and over 90 unique foods produced primarily in high-input systems showed that, per unit of food, organic systems require more land, cause more eutrophication, use less energy, but emit similar greenhouse gas emissions (GHGs) as conventional systems (Michael Clark and David Tilman 2017): “Comparative Analysis of Environmental Impacts of Agricultural Production Systems, Agricultural Input Efficiency, and Food Choice” - Environmental Research Letters, 2017. 12).

Reducing dependency on conventional fertilisers

Suggestions to reduce the dependency on conventional fertilisers:

1.Ban applying of untreated urea: Urea contains 46% of nitrogen. Once applied, soil bacteria elicit urease enzyme to hydrolyse urea molecule. During this process 35-50% of Nitrogen in urea can be lost as ammonia gas. Treating urea with urease inhibitors can protect 60-95% of the lost nitrogen as ammonia. Urea hydrolysis forms ammonium ions, which crops can absorb as nitrogen. Once ammonium ions are formed, they can undergo nitrification and denitrification processes. During nitrification, ammonium ions convert to nitrite and nitrates. Nitrates are much more prone to leaching and runoff and end up in streams. This process can cause up to 80% of nitrogen to be lost. Nitrification inhibitors are available in the market and can be utilised to inhibit the process and save nitrogen and enhance nitrogen utilisation efficiency. Many developed countries adopt these technologies. As far as I know, this technology is not available to Sri Lankan farmers. By adopting the technology, farmers can reduce nitrogen rates significantly.

2.Ban application of all types of fertilisers including organics during periods of heavy rains. Establishing fertiliser application cut off time will reduce run off of fertilisers to streams and will also enhance its utilisation by crops.

3.Adopt the use of highly efficient foliar fertilisers. This will reduce ground applications and enhance fertiliser use efficiency. Spot applications can be done using this method. Novel technology is able to deliver and still be effective at 1L/acre application rate. To my knowledge, this technology is not widely practiced in Sri Lanka.

4.Use of inoculants when growing legume crops. Rhizobium and Bradyrhizobium inoculants can be utilised to cut down 100% of nitrogen requirement by legume crops (soybean, peas, lentils, mungbean, clover etc). Methods of culturing and applying these inoculants will not be that expensive and will not require major investments. Many countries adopted this technology decades ago but surprisingly Sri Lanka has not fully utilised this technology.

5.Mandatory testing for heavy metals and nutrients for all imported fertilisers as well as for fertilisers manufactured and sold in Sri Lanka need to be adopted. Testing should be done by a third-party accredited laboratory before shipping and after arrival at the local port. This will prevent inferior fertiliser products coming into the country.

6.Make decisions based on independent third-party research and not on data supplied by parties with vested interests in importing substandard products. Research and data must be independent and unbiased. Without implementing this process, it will be difficult to use the data for decision making processes.

7.Identify the locally available organic materials for formulating and direct their use in the industry.

8.Establish a national institute such as Organic Material Review Institute (https://www.omri.org/). This institute, as a regulatory body, will form the guidelines and protocols for developing an organic agriculture sector including certifying materials and products to be used in the sector. This is a necessary step before banning of commercial fertiliser and moving to organic agriculture.

Scientific facts are critically important in taking a decision like this and hopefully the catastrophic decision taken will be corrected soon.

I am open to discuss this issue and help in any way I can.

[The writer is CEO and Founder – Active AgriScience Inc. and can be reached via [email protected]. He obtained his Ph.D in Toxicology from Simon Fraser University in Canada in 2010, and his M.Sc. in Plant Science from the University of British Columbia Canada in 2005. His B.Sc is from the University of Peradeniya. He has worked as Director of Research and Development for three leading fertiliser manufacturers in Canada, and successfully developed and marketed innovative fertilisers including microbial inoculants and nitrogen management technologies and holds two patents in this field. He founded Active AgriScience (https://activeagriscience.com/) in 2013 and helped develop high efficiency foliar fertilisers, nitrogen management technologies, and microbial inoculants. The company exports its products to USA, Australia, Germany and UK, with other markets in the pipeline. He has over 25 years of experience in crop nutrition, formulation chemistry, plant growth regulators (PGRs) and other agrochemicals.]