Saturday Feb 28, 2026

Saturday Feb 28, 2026

Monday, 6 July 2020 00:00 - - {{hitsCtrl.values.hits}}

Despite the COVID-19 pandemic in Sri Lanka being a major challenge the country has faced, the Government has taken a prudent and timely approach to eradicate the pandemic and save the lives of the citizens and others in this crisis situation, which is highly admirable.

Despite the COVID-19 pandemic in Sri Lanka being a major challenge the country has faced, the Government has taken a prudent and timely approach to eradicate the pandemic and save the lives of the citizens and others in this crisis situation, which is highly admirable.

With the coronavirus outbreak, the need for disinfectants particularly the demand for sodium hypochlorite-based disinfectants has surged. Paranthan Chemicals being a responsible state-owned company has fully operated its manufacturing capacity and manufactured Sodium Hypochlorite and distributed it to many public authorities, security forces, private institutions and households, working hand in hand with them in this crisis situation to ensure safe and secure Sri Lanka, even at the time when the entire country was under lockdown.

Recently published Interim Guidance by the World Health Organization on ‘Cleaning and Disinfection of Environmental Surfaces in the Context of COVID-19’ highlights the use of chlorine based products such as Sodium Hypochlorite which displays a broad spectrum of antimicrobial activity and is effective against several common pathogens at various concentration.

In addition, Paranthan Chemicals Company Ltd. also performs a vital national role of providing liquid chlorine for national water purification and meeting the chlorine need of the National Water Supply and Drainage Board and thereby contributes on the supply of purified drinking water to the nation.

Chlorine is not only the most widely used water disinfectant but also highly effective against waterborne pathogens. In particular, this helps to prevent the spread of waterborne diseases such as cholera, dysentery and typhoid. In this context too, Paranthan Chemicals also plays an essential role in ensuring public health in Sri Lanka by fulfilling chlorine needs of the nation required for water purification.

Glancing through the history, chlorination at a water treatment plant was made in 1893 in Germany and in 1897, the town of Maidstone in England was the first to have its entire water supply treated with chlorine.

However, permanent water chlorination began in 1905, when a contaminated water supply caused serious typhoid fever epidemic in Lincoln, England and Dr. Alexander Cruickshank Houston used chlorination of the water which helped to prevent the epidemic and as a precaution the chlorination was continued.

Further, the growing demand for hand soap was also observed during this COVID-19 period, as proper hand hygiene is vital and effective in fighting the COVID-19 pandemic. Paranthan Chemicals is connected with better hand hygiene in two fronts. Firstly, it is engaged in the provision of purified water to the nation with its chlorine supplies for water purification. Secondly, its contribution to soap and detergent manufacturing industries with the supply of caustic soda which is the main raw material in manufacturing soaps and detergents, for decades.

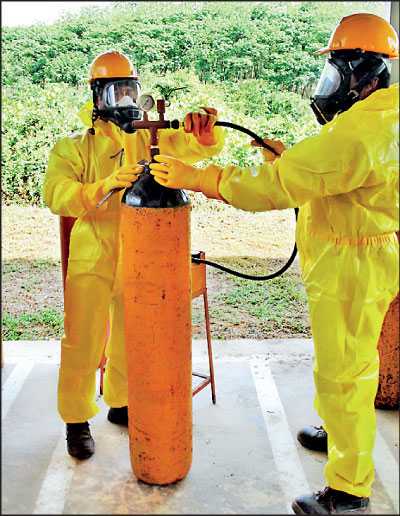

The company has recently established caustic liquid production unit making caustic soda lye is now readily available in the market which not only simplifies the operation of the local manufacturing industries but also reduces the chemical hazards as well as strengthens industrial safety. Paranthan Chemicals is also currently working on expanding the production capacity of ‘Sodium Hypochlorite’. Despite the fact that manufacturing and processing of chemicals is associated with considerable risk factors, it is very commendable that the company has been successful in handling these chemicals backed by decades of accumulated knowledge and technical knowhow.

Paranthan Chemicals Chairman Eng. Upul Ranaweera states, “In line with the expectation of the present Government on achieving self-sufficiency through local production, Paranthan Chemicals is also working on expediting the reestablishment of Paranthan Chemicals Factory in Paranthan in Kilinochchi District, which could manufacture Caustic Soda, Chlorine, Hydrochloric Acid and Sodium Hyphocholoride.”

These chemicals are used as raw material by many local industries such as manufacturing of paper, steel, soaps and detergents, rubber based products, textiles, water purification and in many other industries. With local production of raw material chemical inputs at relatively lower cost, the industries may become more competitive in the world market, thereby increasing Sri Lanka’s exports.

Chairman Upul Ranweera further states, “It could save a significant amount of foreign exchange currently being spent on imports of such chemicals. Accordingly, the company would become the major contributor not only for the upliftment of the local manufacturing industries but also for the national economy.” Interestingly, the main raw material required for the production of caustic soda and chlorine being salt, this could also prosper the local salt manufacturing industry and the country could also maximise the economic benefit from our ocean resources, as well. Paranthan Chemicals Company Ltd. is the pioneer and market leader in the Sri Lankan chemical industry and is currently functioning under the purview of the Ministry of Industry and Supply Chain Management. This is a self-financing institution, contributing dividends to the General Treasury annually.

In a nutshell, Paranthan Chemicals is proud of being associated in the provision of purified water to the nation and supplying chemicals to soaps and detergents manufacturing industries and for other industrial applications, thereby contributing for enhanced public health and creating better hygienic conditions in Sri Lanka.

Paranthan Chemicals Company Ltd. can be proud of its continued commitments towards an infection-free, safe and secure nation and improved quality of life of the people in Sri Lanka.